Mechanization

614 vehicle-based machines:

- Ford

- Volvo

- Scania

- MAN

- Mercedes

European brands attachments:

Gessinknorba and Faun Variopress, BFE

Over 78 thousand units make up the

container and bunker fleet

In a number of Türkiye’nin Regions, Zero-Waste overhauls and builds new container sites

The containers are manufactured according to European standards

(ЕС EN 840-1:2004)

have a cover to prevent the spread of odors and scavenging by animals and birds

Containers for separate waste collection:

- Specialized grid container for SWC

- Specialized galvanised container for SWC

- Specialized 4-piece ballot box for SWC

- Specialized 240 l. containers

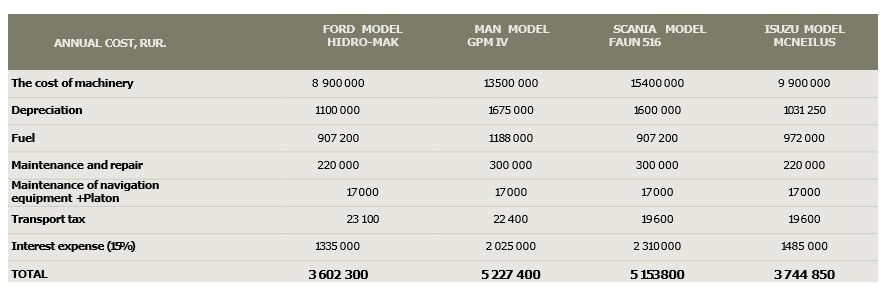

Zero-Waste has analyzed the market of local and imported waste collection vehicles

Based on the evaluation, the priority model is HIDRO-MAK (Turkey), base chassis Ford Cargo 1833DC (Turkey)

Life cycle analysis of special vehicles showed that the leader in terms of cost of removal of 1 м3 (55.2 rubles) is the MAN chassis with the GPM IV 20H25P unit

The second position is occupied by Ford Cargo chassis with HIDRO-MAK unit with the cost of 1 м3 removal – 58.4 rubles. The Ford chassis has a two-axle chassis, which is an advantage for operations in both urban environments and low-traffic settlements

It would make sense to create a fleet based on a single brand of specialized machinery, which would save significantly on maintenance and repair costs through a single service base and the wholesale purchase of spare parts

Model HIDRO-MAK (Türkiye)

base chassis Ford Cargo 1833DC (Türkiye)

Base chassis characteristics

- Power – 330 h.p.

- Eco-class – EURO-5

- Dimensions 8650х2540х3450 мм

- Fuel consumption per 100 km– 42 l

Equipment characteristics

- Useful load volume – 16 m3

- Compaction factor – 5

Cost of HIDROMAK + FORD –

15,5 million rubles per 1 unit

Advantages:

- European quality (part of the market leader KIRCHHOFF Gruppe)

- Minimal electronics, four levers are used to operate the unit. Large production program from the manufacturer

- Three-year warranty on the chassis, according to Turkish representatives. Low cost compared to their European counterparts

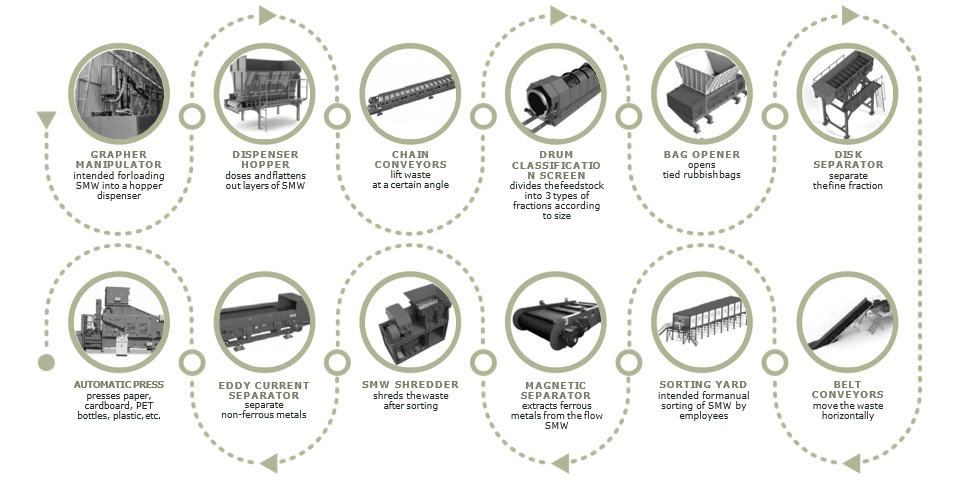

Waste sorting plant

- Reception and processing of waste, including bulky waste

- Primary size separation

- Recovery of secondary raw materials for marketing and recycling

Stages of the technological process*

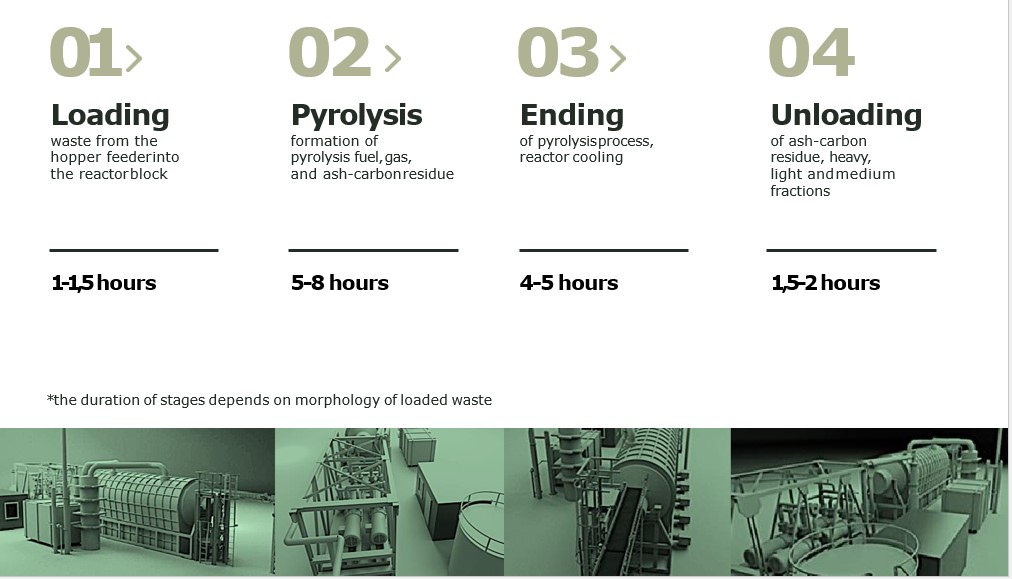

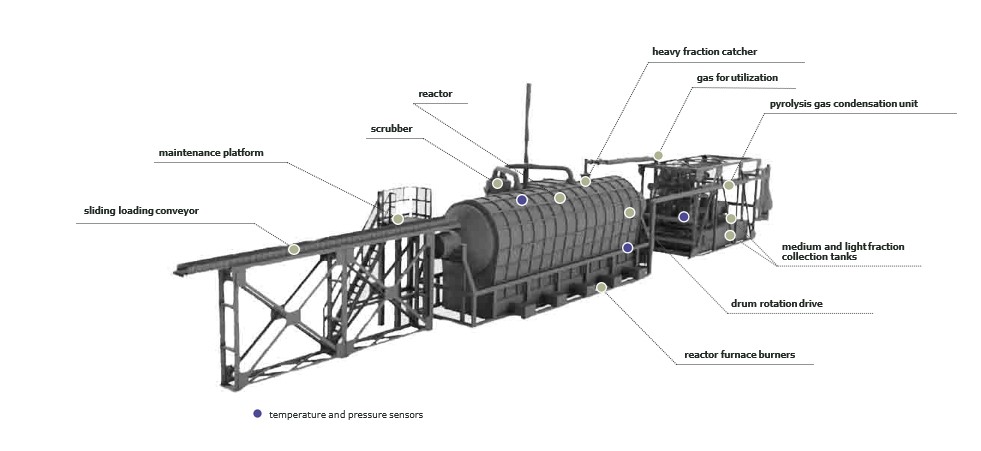

BRP-2 Complex

The proprietary technology for decontamination and recycling of polymer and other organic waste

implemented at the BRP complex is based on the process of contactless decomposition

of organic compounds and polymeric raw materials

Copyright © 2023. All Rights Reserved.| Designed by RealDesign